An Earthship is a type of passive solar house made of natural and recycled materials (such as earth-filled tires), designed and marketed by Earthship Biotecture of Taos, New Mexico. The term is a registered trademark of Michael Reynolds.

|

| Michael Reynolds (1975) |

| ||

| G2 Global model Earthship Taos N.M.., | South and east side of an Earthship passive solar home. |

Earthships are primarily designed to work as autonomous buildings using thermal mass construction and natural cross ventilation assisted by thermal draught (Stack effect) to regulate indoor temperature. Earthships are generally off-the-grid homes, minimizing their reliance on public utilities and fossil fuels. Earthships are built to utilize the available local resources, especially energy from the sun. For example, windows on sun-facing walls admit lighting and heating, and the buildings are often horseshoe-shaped to maximize natural light and solar-gain during winter months. The thick, dense outer walls provide thermal mass that naturally regulates the interior temperature during both cold and hot outside temperatures.

|

| Internal, non-load-bearing walls are often made of a honeycomb of recycled cans joined by concrete and are referred to as tin can walls. |

Internal walls are usually thickly plastered with adobe. Tin can walls can also be used on top of the tire walls ("can and concrete bond beams") as an alternative to wooden shoes. An alternative to these concrete bond beams are wooden bond beams with wooden shoes. The wooden shoes are made using wooden shimming blocks (of 6x6x8' dimensions) placed on top of the wooden bond beam (the latter is basically just 2 layers of 2x12 lumber bolted on concrete anchors (poured blocks of concrete located inside the top tyres). Some rebars are used to "nail" the wooden shoes to the wooden bond beam. The tire walls are additionally strengthened by using concrete in the tires on the ends (called "concrete half blocks"). The roof is made using trusses or vigas (wooden support beams) which rest on the wooden shoes (or tin can walls) placed on the wooden (or concrete) bond beams. The roof as well as the north, east and west facing walls of an Earthship are also heavily insulated to prevent heat loss.

Michael Reynolds' first building, the Thumb House. Built in the early 1970s, it incorporated designs found in later Earthships

The Earthship as it exists today, began to take shape in the 1970s. Mike Reynolds, founder of Earthship Biotecture, a company that specializes in designing and building Earthships, wanted to create a home that would do three things; first, it would be sustainable architecture, using material indigenous to the entire planet as well as recycled materials wherever possible. Second, the homes would rely on natural energy sources and be independent from the "grid", therefore being less susceptible to natural disasters and free from the electrical and water lines that Reynolds considered unsightly and wasteful. Finally, it would be economically feasible for the average person with no specialized construction skills to be able to create.

A building being built of cans in the 1970s

The design used with most earthships. A large series of windows and the use of tires characterize the earthsheltered building

Eventually, Reynolds' vision took the form of the common U-shaped earth-filled tire homes seen today. As a concept, the Earthship was not limited to tires – any dense material with a potential for thermal mass, such as concrete, adobe, earthbags, or stone could theoretically be used to create a building similar to an Earthship.

|

| The earth-rammed tire is used in the vast majority of Earthships. |

Rammed-earth and tires are easily accessible and allow for owner build structures and use of untrained labour. Scrap tires are plentiful around the world and easy to come by; there are an estimated 2 billion tires throughout the United States. As of 1996, as many as 253 million scrap tires were being generated each year in the United States, with 70% being reclaimed by the scrap tire market (leaving perhaps 75 million scrap tires available for reuse as whole tires).[1] The method by which scrap tires are converted into usable "bricks" (the ramming of the earth) is simple and affordable but labour intensive.

The earth-rammed tires of an Earthship are usually assembled by teams of two people working together as part of a larger construction team. One member of the two person team shovels dirt, which usually comes from the building site, placing it into the tire one scoop at a time. The second member, who stands on the tire, uses a sledge hammer to pack the dirt in. The second person moves in a circle around the tire to keep the dirt even and avoid warping the tire. These rammed earth tires in an Earthship are made in place since they can weigh as much as 300 pounds and therefore can be difficult to relocate.

Additional benefits of the rammed earth tire are its high load-bearing capacity and its resistance to fire.

A fully rammed tire, which is about 2 feet 8 inches wide, is massive enough to surpass conventional requirements for structural load distribution to the earth. Because the tire is full of soil, it does not burn when exposed to fire. In 1996 after a fire swept through many conventional homes in New Mexico, an Earthship discovered in the aftermath was relatively unharmed. Only the south-facing wall and the roof had burned away.

Currently, Earthships are in use in almost every state in the United States and Canada, as well as many European countries. The colder climates require the use of strong insulation on the outside of the tire walls, which was not common in earlier designs. Building an Earthship in a Cold Climate? Earthships are continually being built around the world by Taos based Earthship Biotecture. In addition, books, plans and training sessions (Earthship Academy) are made available by Reynolds. This owner builder approach together with the use of inexpensive materials has inspired people worldwide to build their own passive solar homes.

Systems

The Earthship was designed as a structure that would be free of the constraints of centralized utilities, on which most modern shelters rely. Earthships must be able to create their own utilities, and to utilize readily available sustainable materials. In order to be entirely self-sufficient, the Earthship needs to be able to handle the three systems of water, electricity, and climate.

Water

|

A domestic rainwater harvesting system

|

Collection

Earthships are designed to catch and use water from the local environment without bringing in water from a centralized source. Water used in an Earthship is harvested from rain, snow, and condensation. As water collects on the roof, it is channeled through a silt-catching device and into a cistern. The cisterns are positioned so they gravity-feed a WOM (water organization module) that filters out bacteria and contaminants and makes it suitable for drinking. The WOM consists of filters and a DC-pump that are screwed into a panel. Water is then pushed into a conventional pressure tank to create common household water pressure.

Water collected in this fashion is used for every household activity except flushing toilets. The water used for flushing toilets has been used at least once already: frequently it is filtered waste-water from sinks and showers, and described as "Greywater".

Greywater

Greywater, used water that is unsuitable for drinking, is used within the Earthship for a multitude of purposes. First, before the greywater can be reused, it is channeled through a grease and particle filter/digester and into a 30"-60" deep rubber-lined botanical cell, a miniature living machine, within the Earthship. With embedded plants, this filter also potentially can be used to produce food (for example, by using a fruit tree).

Oxygenation, filtration, transpiration, and bacteria-encounter all take place within the cell and help to cleanse the water. Within the botanical cell, filtration is achieved by passing the water through a mixture of gravel and plant roots. Because of the nature of plants, oxygen is added to the water as it filters, while nitrogen and phosphate is removed. Note that plant root cells do not produce oxygen but consume it; only the leaves of plants produce oxygen. Water taken up through the plants and transpired at their tops helps to humidify the air. In the cell, bacteria will naturally grow and help to cleanse the water.

Water from the low end of the botanical cell is then directed through a peat-moss filter and collected in a reservoir or well. This reclaimed water is then passed once more through a greywater board and used to flush conventional toilets.

Often, greywater made at earthships is not polluted enough to justify treatment (its "pollution" being usually just soap, which is often not environmentally damaging). At earthships, plants are placed at outlets of fixtures to regain the water and the nutrients lost (e.g. from the soaps). Usually, a single plant is placed directly in front of the pipe, but mini drain-fields are also sometimes used. The pipe is made large enough (5,08 cm) so that the formation of underground gas (from the greywater) is avoided. This is done with kitchen and bathroom sinks, and even showers, washing machines, and dishwashing machines. The plants are usually placed indoors with the sinks and outdoors with the washing/dishwashing machines and shower (to avoid indoor "floods"). Also, with the latter, larger drain-fields are used instead of a mere plant being placed before an outlet.

| |

| Black Water - | The water system with integrated flush toilet, as used in most earthships |

Black water

Black water, water that has been used in a toilet, was usually not created within many of the earliest earthships as the use of conventional toilets was discouraged. Instead, in the early days composting toilets were advocated, which use no water at all. However, with the new greywater treatment system design (as used in Nautilus and Helios) created by Michael Reynolds, flush toilets have now found a place in the earthship and the general water system has been redesigned according to the new "6-step process".

Now, when the newly included flush-toilets are used, blackwater is not reused within the Earthship. Instead, blackwater is sent to a solar-enhanced septic tank with leach-field and planter cells (the whole being often referred to as the "incubator"). The solar-enhanced septic tank is a regular septic tank which is heated by the sun and glazed with an equator-facing window. The incubator stores the sun's heat in its concrete mass, and is insulated, to help the anaerobic process. Water from the incubator is channeled out to an exterior leach field and then to landscaping "planter cells" (spaces surrounded by concrete in which plants have been put). The cells are similar to the botanical cell used in greywater treatment and are usually placed just before and under the windows of the earthship.

In cases where it is not possible to use flush-toilets operating on water, dry solar toilets are now advocated, instead of regular composting toilets. If this is the case, no black water is formed and the use of an incubator is thus (usually) not necessary. Instead, regular "planters" (plants used for sucking up water/nutrients) are then used. When using regular planters as well, no chemical soaps or detergents can be used.

The space where the WOM (water organization module), graywater pump panel, pressure tank, (first set of) batteries, and POM (power organising module) are stored is in a small room referred to as the "systems package".

|

| Self-sufficient, Sustainable, Water Collection to use and renew, sun & wind generate electricity, recycled building materials, |

Electricity

Earthships are designed to collect and store their own energy from a variety of sources. The majority of electrical energy is harvested from the sun and wind. Photovoltaic panels and windturbines located on or near the Earthship generate DC energy that is then stored in several types of deep-cycle batteries. The space in which the batteries are kept is usually a special, purpose-built room placed on the roof. Additional energy, if required, can be obtained from gasoline-powered generators or by integrating with the city grid.

In an Earthship, a Power Organizing Module is used to take stored energy from batteries and invert it for AC use. The Power Organizing Module is a prefabricated system provided by Earthship Biotecture that is simply attached to a wall on the interior of the Earthship and wired in a conventional manner. It includes the necessary equipment such as circuit breakers and converters. The energy run through the Power Organizing Module can be used to run any house-hold appliance including washing machines, computers, kitchen appliances, print machines, and vacuums. Ideally, none of the electrical energy in an Earthship is used for heating or cooling.

|

| Drainage Channel, Sunlight |

Climate

The interior climate of an Earthship is stabilized by taking advantage of natural phenomena. Mainly, the Earthship is designed to use the properties of thermal mass and passive solar heating and cooling. Examples are large front windows with integrated shades, trombe walls and other technologies such as skylights or Steve Baer's "Track Rack" solar trackers (doubling as an energy generation device and passive solar source).

The load-bearing walls of an Earthship, which are made from steel-belted tires rammed with earth, serve two purposes. First, they hold up the roof, and second, they provide a dense thermal mass that will soak up heat during the day and radiate heat during the night, keeping the interior climate relatively comfortable all day.

In addition to high thermal mass, some Earthships may be earth-sheltered. The benefits of earth-sheltering are twofold because it adds to the thermal mass and, if the Earthship is buried deep enough, allows the structure to take advantage of the Earth's stable temperature.

The Earthship is designed in such a way that the sun provides heating, ventilation, and lighting. To take advantage of the sun, an Earthship is positioned so that its principal wall, which is nonstructural and made mostly of glass sheets, faces directly towards the equator. This positioning allows for optimum solar exposure.

To allow the sun to heat the mass of the Earthship, the solar-oriented wall is angled so that it is perpendicular to light from the winter sun. This allows for maximum exposure in the winter, when heat is wanted, and lesser exposure in the summer, when heat is to be avoided. Some Earthships, especially those built in colder climates, use insulated shading on the solar-orientated wall to reduce heat loss during the night.

|

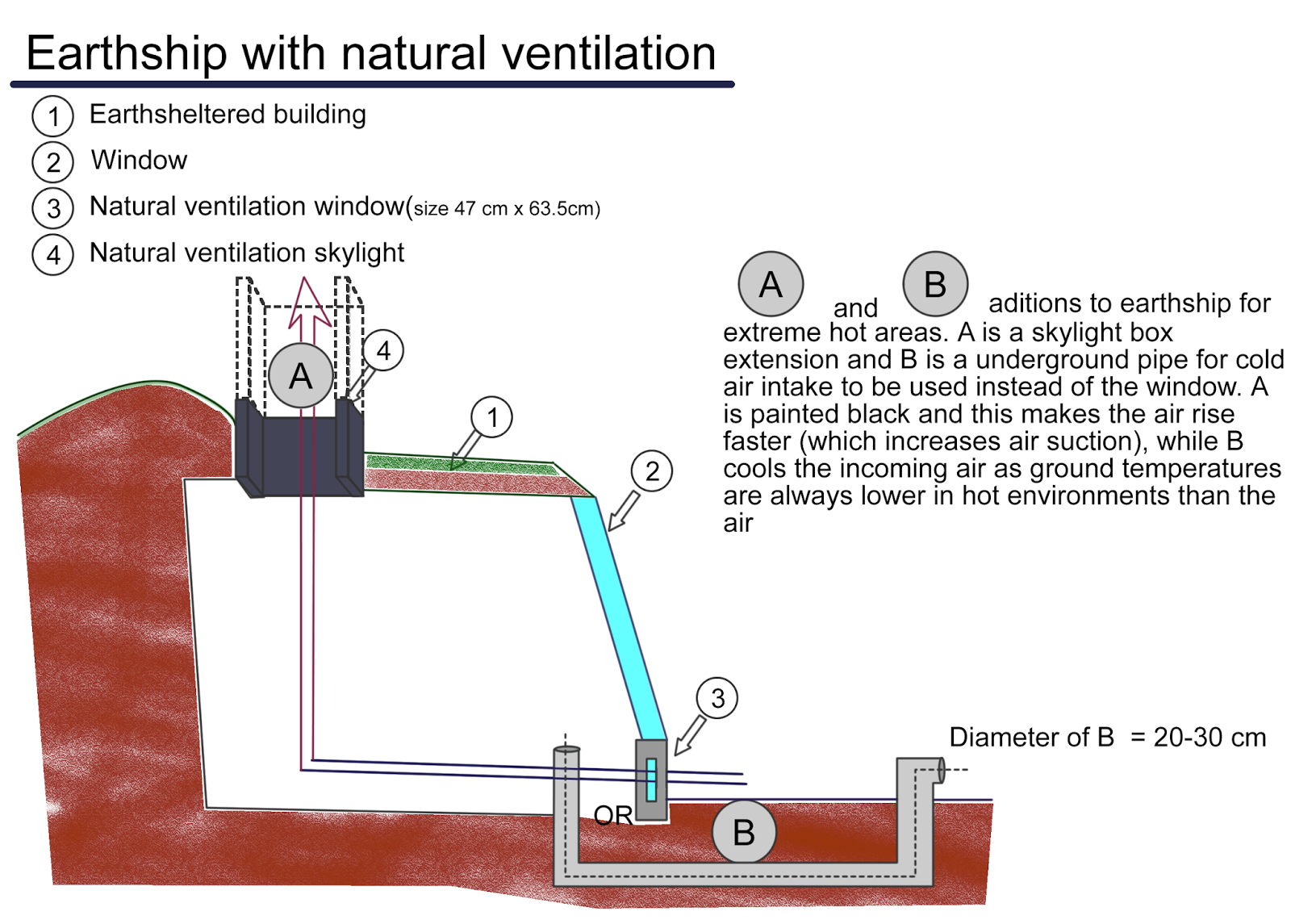

Natural ventilation

Natural convection cooling an Earthship

The earthships usually use their own natural ventilation system. It consists of cold(er) air coming in from a front ("hopper") window, especially made for this purpose and flowing out through (one of) the skylights that are placed on the earthship. As the hot air rises, the system creates a steady airflow - of cooler air coming in, and warmer air blowing out.

|

| Earth Tubes |

Heating problems

Earthships rely on a balance between the solar heat gain and the ability of the tire walls and subsoil to transport and store heat. The design intends to require little if any auxiliary heat. Some earthships have suffered from overheating and some from overcooling.

Some earthships appear to have serious problems with heat loss. In these cases heat appears to be leaking into the ground constantly during the heating season and being lost. This situation may have arisen from the mistaken belief that ground-coupled structures (building in thermal contact with the ground) do not require insulation. The situation may also be due to large climatic differences between the sunny, arid, and warm Southwest (of the USA) where earthships were first built and the cloudier, cooler, and wetter climates where some are now being built. Malcolm Wells, an architect and authority on earth-sheltered design, recommends an imperial R-value 10 insulation between deep soils and heated spaces. Wells's insulation recommendations increase as the depth of the soil decreases.

In very limited and specific situations, uncommon during the heating season, thermal mass can marginally increase the apparent R-value of a building assembly such as a wall. Generally speaking thermal mass and R-value are distinct thermodynamic properties and should not be equated. Thermal performance problems apparently seen in some earthship designs may have occurred because of thermal mass being erroneously equated to R-value. The imperial R-value of soil is about 1 per foot.

Africa

The first earthship in South Africa was built by Angel and Yvonne Kamp from 1996 to 1998. They rammed a total of 1,500 tires for the walls. The earthship, near Hermanus, is located in a 60 hectare private nature reserve which is part of a 500000 hectare area enclosed in a game fence and borders the Walker Bay Nature Reserve.

The second earthship in South Africa is a recycling centre in Khayelitsha run as a swop shop concept. The centre was finished in December 2010.Another low cost house built with tyres is in development in Bloemfontein.

A project nearing completion in South Africa is a combined living quarters for 4 to 5 people, a bed and breakfast, and an information/training centre in Orania.This earthship is based on the global earthship model and is built with a foundation of tyres, has roof bearing walls built with earthbags, and interior walls built with cob, cans and plastic bottles. This earthship adheres to all six principles of an earthship. This is the largest earthbag earthship in the world.

A residential house is in the planning phase for Swaziland.

In 2011, construction began on the Goderich Waldorf School of Sierra Leone. The school was the first educational institution to use earthship architecture. Although Mike Reynolds and a team of interns helped complete the first two classrooms, the majority of the building was built by community members who had been trained in Reynolds' building techniques.

0 comments:

Post a Comment